AN

It is a fully artificial light type plant factory using an agricultural greenhouse.This system allows planted seedlings to grow while automatically circulating in the cultivation room, and allows workers to harvest without entering the cultivation room, therefore reducing the risk of contamination by foreign matter and the burden on the workers.

Your existing agricultural greenhouses can be used. It is also possible to construct a plant factory using farmland.The inside of the greenhouse can be automatically controlled to provide an optimal growing environment for lettuce, allowing for stable and safe cultivation.

Possible to cultivate large, thick, crispy, high quality lettuce in a stable condition. Suitable for commercial use, cut vegetables, etc. Cultivation of lettuce such as frill lettuce, batavia lettuce, and romaine lettuce is possible.

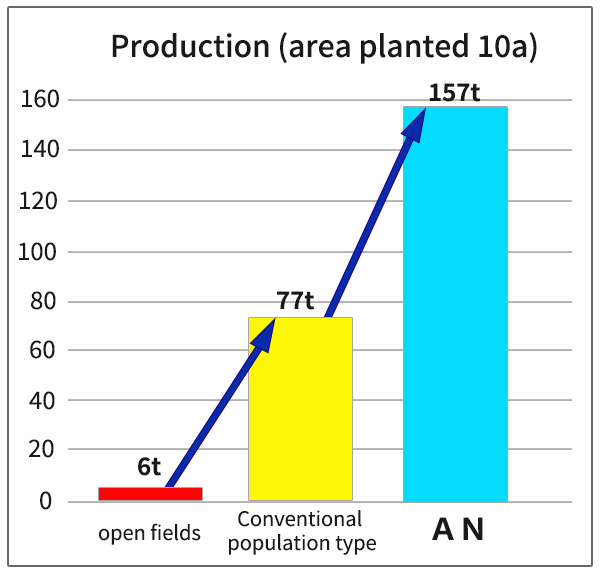

AN Cultivation performance

High value-added, high quality and the needs of large demand customers can be realized at the same time.

Fully artificial light type plant factory『AN』

| Annual harvest weight per 10a planted area

(After transplanting in the field) |

157 t/year |

| Weight per plant | 300 g |

| Yield and commercialization rate per lettuce plant | 90% |

| Number of bacteria | 10² |

※ Crop yield is based on interviews with producers.

※The number of bacteria is measured by an inspection company.

※The values are based on cultivation examples and are not guaranteed.

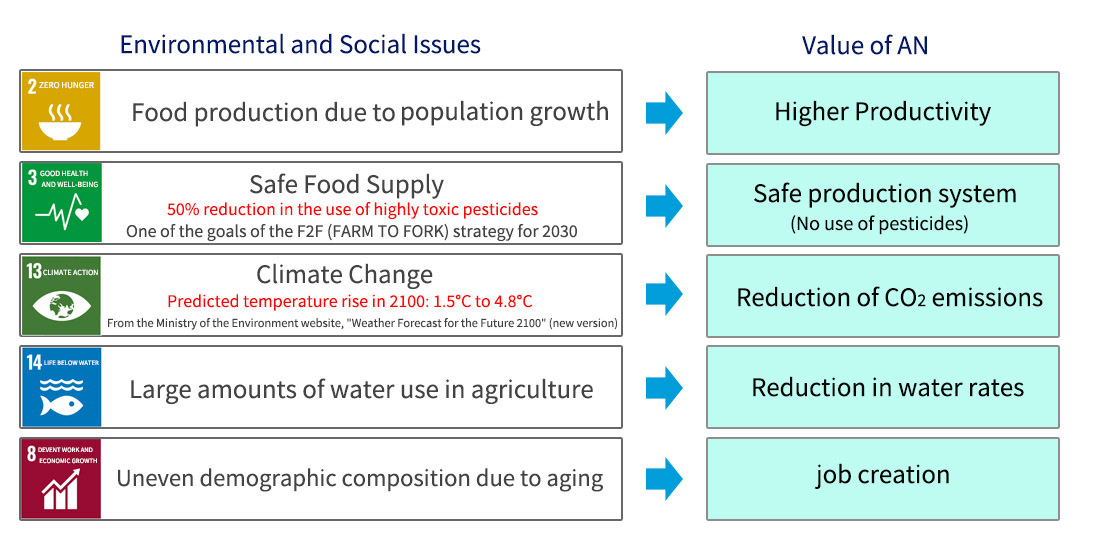

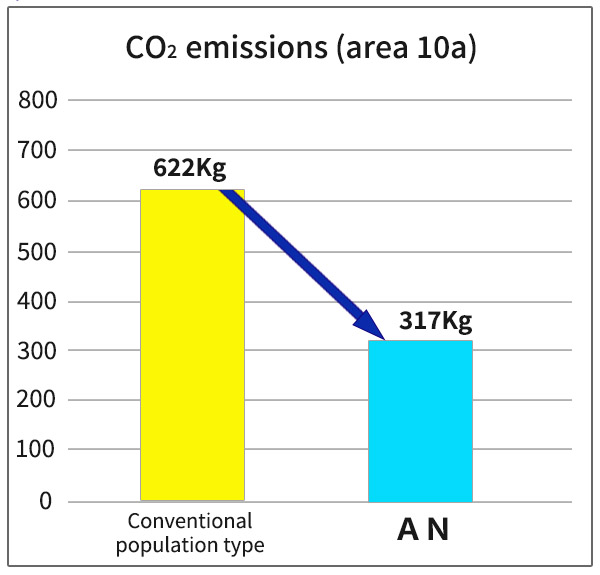

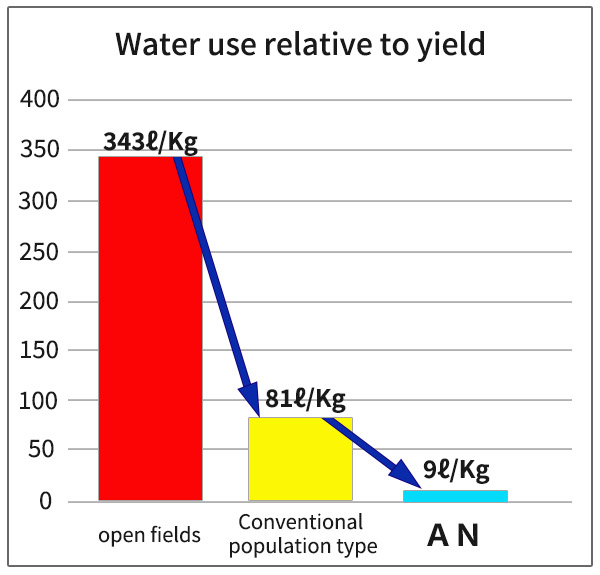

Contribution to SDGs

※The values of conventional fully artificial lightvtype plant factory were estimated on the basis of actual results from the test farms of our group companies or our own test farms.

※The CO2 values were estimated from our CO2 emission coefficient of 0.441 kg-CO2/kWh in FY2020 published by TEPCO Energy Partner, based on the amount of electricity consumed.

※The figures given are based on cultivation cases and are not guaranteed values.

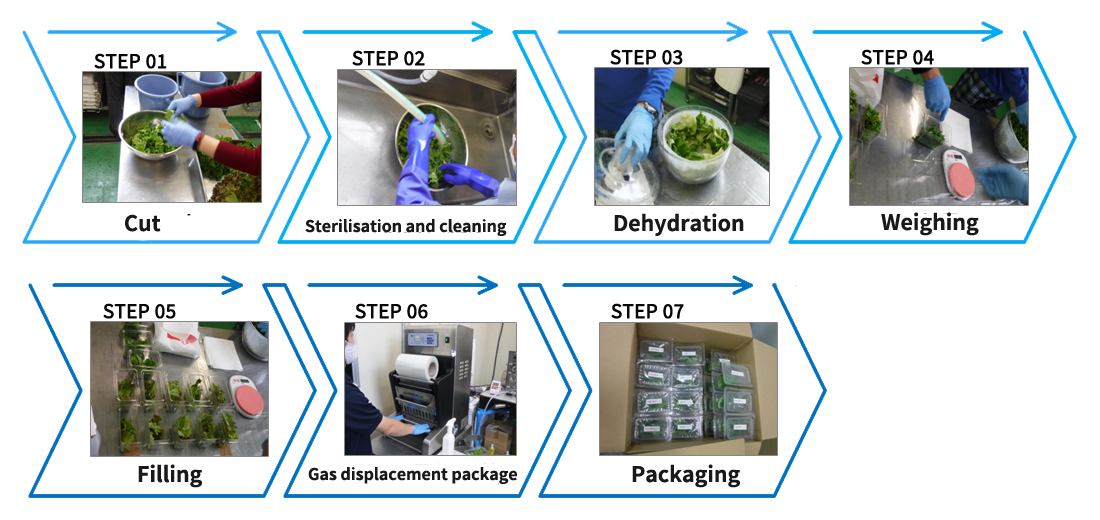

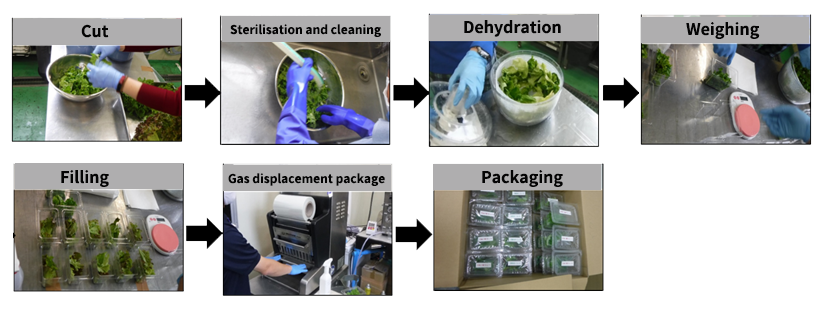

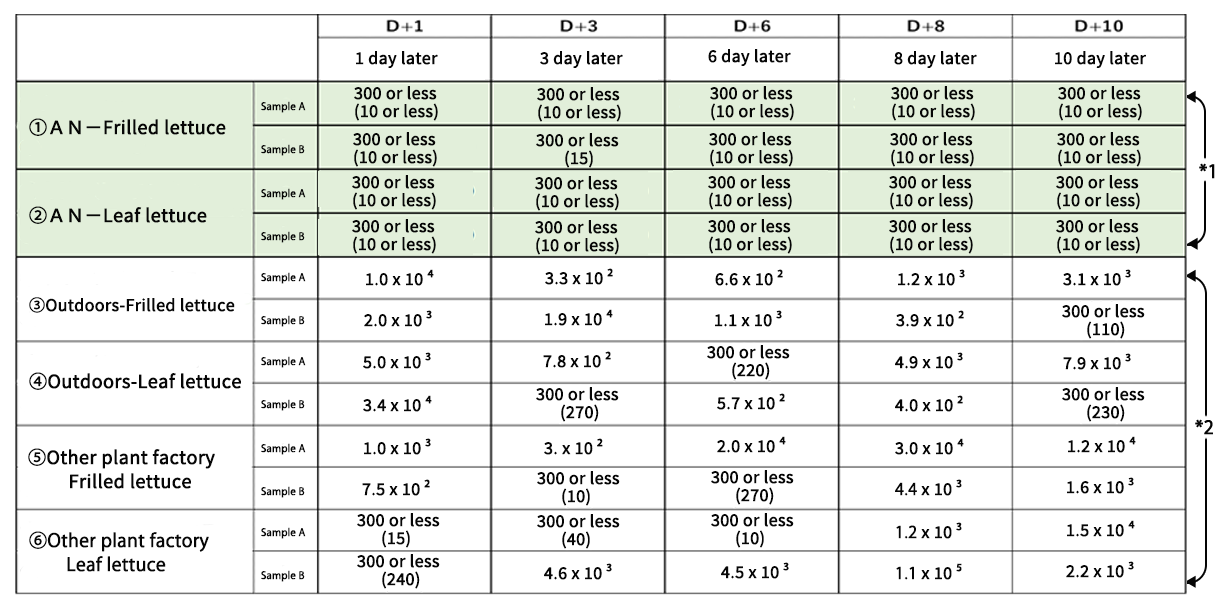

Handling of processed products, Measurement bacteria counts

Measurement bacteria counts are implemented

Six varieties (3 cultivation methods x 2 varieties) were processed and tested using the following procedures

Inspection Summary

| Varieties | Frilled lettuce, Leaf lettuce |

| Cultivation method | Cultivation in AN system, outdoor cultivation, cultivation in other plant factories |

| Number of Samples | 120 *3 cultivation methods, 2 varieties 6 x 20 |

| Bacteria count inspection company | Ikari Sterilization Co. |

| Bacteria count method | General viable bacteria count standardized observation plate method (mixed culture method) |

Lettuce to be tested is cut, sterilized and washed (once), dehydrated, weighed, filled, and gas displacement packaged to prepare samples. After packaging, the samples are stored refrigerated at 5°C. The testing period was from the day after the packaging date to 10 days later, and a total of five tests were conducted.

|

※1 There is almost no variation in the number of bacteria depends on passage of time.

※2 There are variations in the number of bacteria depending on the samples.

Difficult to maintain consistent quality.

Additional sterilization washing frequency and time are necessary to reduce variation in the number of bacteria.

Mitsubishi Chemical Group “Water and Food for the Future” section

How do you see the future in 2050?

The Mitsubishi Chemical Group aims to create a society in which all current social issues have been resolved.

In the “Knock on the Earth” series of corporate advertisements, the MCHC Group presents its vision of the future and the solutions that will help realize it.

The “Water and Food for the Future” section depicts an environmentally friendly world where people do not have to worry about food and water, and the MCHC Group is working toward a sustainable food supply system and recycling of water resources.

* Taken from the MCHC Group’s official channel

AN Joint Development Company

It is possible to grow large, high-quality lettuce weighing more than 300g.

Fresh, large lettuce is suitable for processing and industrial use.